MEMS, or Micro-Electro-Mechanical Systems, represent a technology that integrates mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology. MEMS technology enables the production of tiny devices that can perform mechanical and electrical functions. These devices find applications across a wide range of fields, including automotive sensors, medical devices, and consumer electronics. In this overview, we'll look at the basic features of MEMS systems and their classifications.

Basic Features of MEMS Systems

-

Miniaturization: MEMS devices are characterized by their small size, usually ranging from a few micrometers to a millimeter. This miniaturization allows for reduced material usage, lower power consumption, and the integration of multiple functions on a single chip.

-

Integration: MEMS integrate mechanical and electrical components within a single device. This integration can significantly reduce the size and cost of the device while improving its performance.

-

Microfabrication: The production of MEMS devices is based on microfabrication techniques similar to those used in semiconductor manufacturing, such as photolithography, etching, and deposition. These processes allow for the precise control of the geometry and properties of the materials used.

-

Multi-Disciplinary: The design and manufacture of MEMS devices involve knowledge from various fields, including mechanical engineering, electrical engineering, materials science, and microfabrication technology.

-

Functionality: MEMS can perform a wide range of functions, including sensing physical parameters (like pressure, temperature, and motion), actuation (movement and force generation at micro scales), and control.

Classifications of MEMS Systems

MEMS systems can be classified based on their function or application area. A broad classification includes:

-

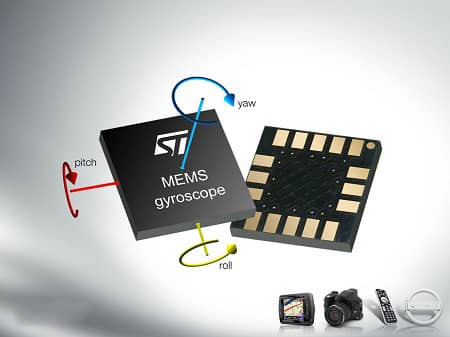

Sensors: These devices convert physical stimuli (such as mechanical motion, light, heat, or chemical composition) into measurable electrical signals. Examples include accelerometers, gyroscopes, pressure sensors, and microphones.

-

Actuators: MEMS actuators use electrical energy to produce mechanical motion. Examples include microvalves for control of gas and fluid flows, micromirrors for optical applications, and resonators for signal processing.

-

Microfluidics: This area involves the manipulation of small volumes of fluids (nanoliters or picoliters) using microfabricated channels and valves. Applications include lab-on-a-chip devices, DNA chips, and drug delivery systems.

-

RF MEMS: These devices are used in the radio frequency domain for telecommunications. They include switches, capacitors, and resonators that have applications in mobile phones, satellite communication, and radar systems.

-

BioMEMS: BioMEMS involve the integration of MEMS devices with biological systems. Applications include biosensors for detecting pathogens or toxins, microfluidic devices for analyzing DNA, and implants for drug delivery or monitoring physiological functions.

MEMS technology continues to evolve, with research focused on developing new materials, fabrication methods, and applications. These advancements are expected to lead to even smaller devices with enhanced functionality, opening up new possibilities in electronics, healthcare, environmental monitoring, and beyond.